Visual Information

Visual displays

Visual management

Visual Thinkers

VALUES WE SWEAR BY

Inspiring facilities through effective

- LEADERSHIP

- INTEGRITY

- RESPONSIVENESS

- RESPONSIBILITY

Features that you are gonna Love

5S

5S stands for the 5 steps of this methodology: Sort, Set in Order, Shine, Standardize, Sustain.

7 QC Tools

The 7 QC tools are fundamental instruments to improve the process and product quality.

FMEA

Failure Modes and Effects Analysis Failure Modes and Effects Analysis is a systematic.

PokoYoke

Poka-Yoke is a process improvement designed to prevent a specific defect from occurring.

PPAP

Production Part Approval Process (PPAP) is a valuable tool for establishing confidence in component suppliers.

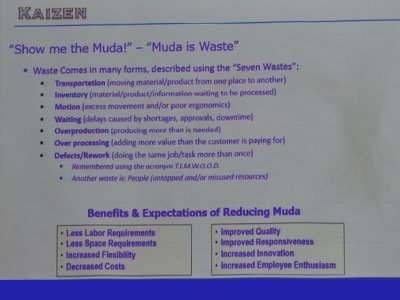

KAIZEN

Kaizen is a Japanese term meaning "change for the better" or "continuous improvement.

7 Wastes

Under the lean manufacturing system, overproduction, inventory, motion, defects, over-processing, waiting.

Value stream Mapping

A value stream map all the important steps of your work process necessary to deliver value from start to finish.

Jidoka

Jidoka is a Japanese word modified by Toyota. The original word was and simply means automation.